THC Reduction System for Industrial Facilities

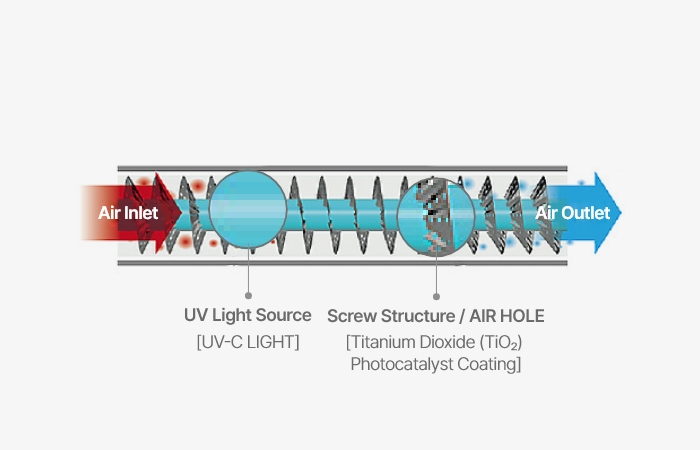

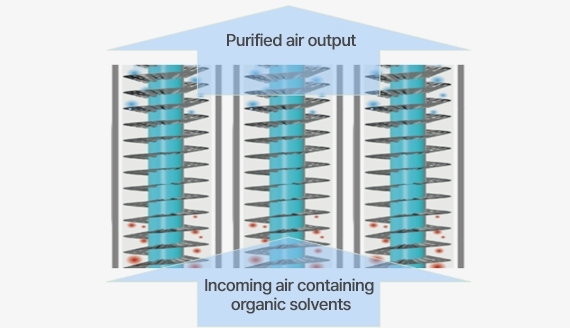

Photocatalytic Purification System Using photochemical reactions to decompose harmful substances and organics

CheomdanLab has developed an eco-friendly system that doesn’t require consumables and allows permanent use with an optimized special module. by localizing materials that were previously reliant on imports, costs are reduced while establishing an eco-friendly air purification system.

What is Total Hydrocarbons (THC)?

- Total Hydrocarbons (THC) refers to the total amount of hydrocarbon compounds in the atmosphere, encompassing all organic compounds, including volatile organic compounds (VOCs) that are composed of carbon and hydrogen. These compounds are primarily emitted from sources such as automobiles, the painting industry, the printing industry, oil storage and distribution facilities, dry cleaning facilities, and road paving (asphalt). Hydrocarbons exist in various forms, and many of them act as greenhouse gases, directly contributing to climate change.

- For example, methane (CH₄), a type of hydrocarbon, is approximately 25 times more potent as a greenhouse gas than carbon dioxide (CO₂), meaning even a small amount in the atmosphere significantly impacts climate change. VOCs also react with nitrogen oxides (NOx) in the atmosphere to create ground-level ozone, which is a powerful greenhouse gas. Therefore, reducing THC not only limits the formation of these secondary pollutants but also decreases greenhouse gas emissions, playing a vital role in achieving carbon neutrality.

Volatile Organic Compounds (VOC)

- Hydrocarbon compounds that generate photochemical oxidants through photochemical reactions with nitrogen oxides (NOx) and other chemicals in the atmosphere, resulting in ozone (O₃), which is a primary component of photochemical smog.

- 37 types of volatile organic compounds are designated by the Ministry of Environment.

- Impacts of VOCs

- Carcinogenic and generally harmful to human health

- Destruction of the ozone layer and global warming

- Odor generation

- Formation of photochemical smog (causing eye irritation, reducing visibility, and contributing to acid rain through the oxidation of SO₂ in the atmosphere)

THC Reduction Equipment

Industries that use large amounts of organic solvents, such as chemical manufacturing, tend to have relatively high levels of THC and are required to install THC reduction devices. The emission standards for THC primarily cover hydrocarbons and benzene, while there are no specific standards for styrene, ethylbenzene, etc. As a result, THC emissions are regulated based on the total hydrocarbon amount.

Activated Carbon

Filter Issues

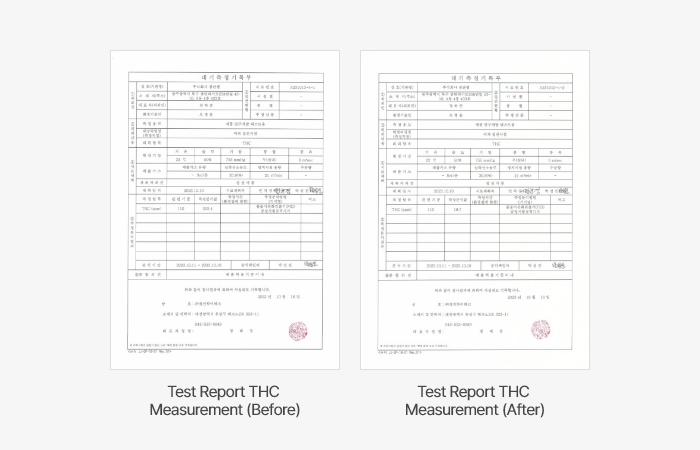

- Average THC removal efficiency: 41.0%

- Difficulty in replacing activated carbon according to replacement cycle

- Operating adsorption towers with degraded activated carbon

- Unstable maintenance of prevention facilities

- Primary use of activated carbon; adsorption efficiency decreases as adsorption time increases, necessitating replacement

- Activated carbon is a consumable with a limited lifespan

- Air pollution from degraded activated carbon (fine carbon dust emission)

- Need for facilities and systems to recycle used activated carbon ⭢ classified as industrial waste due to the spent adsorbent

- Generation of secondary pollutants released into the air when removing adsorbed harmful substances

- Mandatory outsourcing to designated waste disposal companies

Alternative to

Activated Carbon

CheomdanLab Photocatalytic

Purification System

- High THC removal efficiency: 91.6%

- Composed of photocatalytic screw filter, UV lamp, and stabilizer

- No need for photocatalytic filter replacement (semi-permanent use)

- Easy maintenance of prevention facilities

- ESG management-compatible photocatalytic purification system

- Semi-permanent photocatalytic filter structure

- Environmentally friendly technology for reducing industrial greenhouse gases, supporting carbon neutrality

- Catalytic decomposition with no residual substances post-reaction

- Effective replacement for activated carbon, reducing import dependency

- Lower maintenance costs and easier operation compared to high initial cost of activated carbon adsorption towers