Silicon Nitride Balls for Bearings

Localization of Silicon Nitride (Si₃N₄) Bearing Balls, a Core Material in High-Value-Added Industries like Electric Vehicles (EVs) and Semiconductors

Silicon Nitride (Si₃N₄) Balls

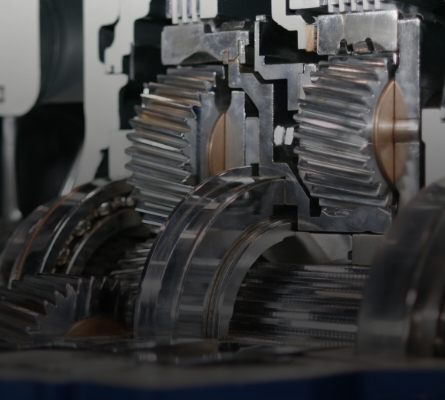

Our Silicon Nitride (Si₃N₄) ceramic balls are produced using Modified SRBSN technology, achieving high strength, superior fracture toughness, and excellent wear resistance. This makes them ideal as essential components in high-speed, high-performance bearings due to their strong resistance to rolling contact fatigue.

Silicon Nitride Ball Manufacturing Process

- Other Companies

-

Step 1

Expensive Si₃N₄ raw powder

-

Step 2

Si₃N₄ sphere forming technology

-

Step 3

Si₃N₄ sintering technology - GPSSN

-

Step 4

Precision processing technology of spherical sintered body

- CheomdanLab

-

Step 1

Silicon scrap grinding to powder

-

Step 2

Silicon sphere forming technology

-

Step 3

Si₃N₄ sintering technology – SRBSN

-

Step 4

Precision processing technology of spherical sintered body

Product Details

| Property | Traditional Steel Ball | CheomdanLab’s Silicon Nitride Ball | Remarks |

|---|---|---|---|

| Density(g/cm³) | 7.6 | 3.20 ~ 3.25 | Very Good |

| Hardness(HV) | 700 | 1,400~1,600 | Very Good |

| Elastic Modulus(GPa) | 190 | 320 | Very Good |

| Fracture Toughness(MPa•m1/2) | - | 6.0 ~ 7.0 | - |

| Max. Operating Temperature | 320 | 1,000 | Very Good |

| Magnetism | Yes | No | Very Good |

| Conductivity | Yes | No | Very Good |

Applications

-

Hybrid bearings for electric vehicles

-

High-vacuum pump bearings for semiconductor processing

-

High-speed rotation bearings for aerospace

-

Wind turbine bearings

-

Ball mill crushing balls

Non-oxide ceramic grinding in semiconductors, and frit grinding for glass raw materials.